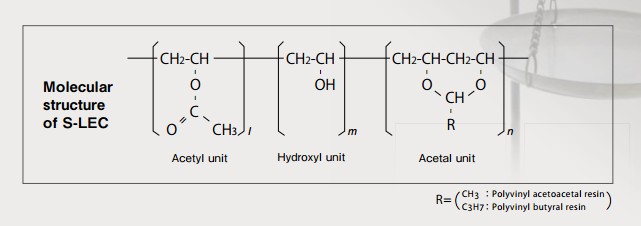

SEKISUI Specialty Chemicals is pleased to offer proprietary S-LEC B/K polyvinyl acetal resin. The product’s three units, acetyl, acetal and hydroxyl, lend its grades valuable properties. Containing a polar group as well as a nonpolar group, the resin helps customers pinpoint their processing results per their unique application. Molecular-level bonding and release control allows for extensive versatility in manufacturing.

SEKISUI tailors S-LEC B/K’s chemical and physical properties, such as its strength, viscosity, adhesiveness, solubility and flexibility, by varying its three units’ weight ratio and degree of polymerization.

Key Properties of S-LEC B/K

As a multiuse polyvinyl acetal resin, S-LEC B/K extends exemplary properties to product development:

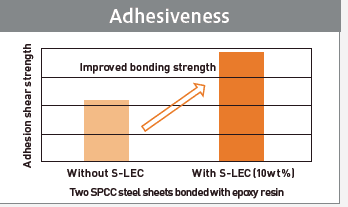

- Bonding strength. Materials achieve robust adhesion and cohesion.

- Toughness. The product makes both hard and soft substances stronger and more pliable.

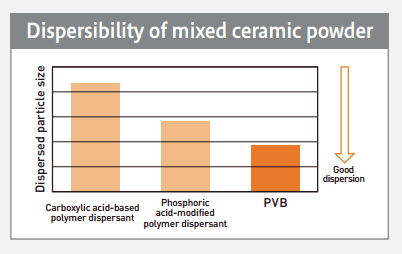

- Dispersibility. Materials that tend to aggregate distribute evenly, with greater solvency.

S-LEC B/K also creates greater levelability and moldability, further enhancing products during and after manufacturing. This polyvinyl acetal resin is highly compatible with a range of chemical structures, suitable for adhesives, emulsions and more. Altogether, its properties’ versatility allows customers to add stability, strength and solvency in varying degrees.

See S-LEC B/K grades and their physical properties.

S-LEC B/K Polyvinyl Acetal Resin Applications

S-LEC B/K polyvinyl acetal resin is key to durable, precision products in wide-ranging applications.

Manufacturers use S-LEC B/K in prepreg composites for aerospace applications due to its strength, moldability and flexibility (via Pexels).

Ceramic Binder

Incorporating polyvinyl acetal resin into ceramic formulations creates tougher, more flexible end products. Its improved adhesion strengthens bonds between ceramic particles and the binder matrix while making the ceramic body more pliant.

S-LEC B/K molecules have both “pulling” (hydroxyl unit) and “non-pulling” properties, leading to good sheet strength. As a result, it produces peel- and breakage-resistant bonding conditions. This characteristic is critical for ceramic manufacturing processes and products, including electrical ceramics.

Microchips and Electronics

S-LEC B/K’s use in future-focused microchips and electronics is one of its most innovative applications. As a binder for inner dielectric layers, its toughness, adhesion and dispersibility enable the creation of ultra-thin ceramic sheets. Additionally, its excellent dispersibility and dimensional stability during sintering facilitate the creation of consistent, high-precision ceramic components.

These characteristics contribute to electronic components’ reliability and performance, including crack- and shock-resistant microchips, LCD displays, substrates, circuit boards, printed ceramic chips and semiconductors.

Prepreg Composites

Polyvinyl acetal resin is a toughener and modifier in prepreg composites, with epoxy bonding to strengthen carbon fiber and honeycomb composites alike. S-LEC B/K maintains the material’s structural integrity while remaining shock absorbent and impact resistant.

Additionally, S-LEC B/K creates stronger adhesion between matrices, fibers and other multilayer composites. Reduced brittleness, warpage and shrinkage, alongside improved processability, lead to high-performance prepreg composites. The customer can thus manufacture high-stress products for aerospace and vehicle applications, among many others.

S-LEC B/K leads to significantly improved bonding strength in steel sheets.

Printing Inks

S-LEC B/K’s low-viscosity polyvinyl acetal resin grades ensure uniform ingredient distribution in flexographic and gravure printing. When used in printing inks and ink slurries, S-LEC B/K resins create a smooth surface after application. Its fine distribution of components creates a flat, level finish. Its ability to evenly distribute powder particles (e.g., pigments) is a crucial advantage for the end product.

Alcohol-soluble and available in multiple formulations, S-LEC B/K offers customizable viscosity through changes in composition, degree of polymerization and other factors.

[Related: Polyvinyl Alcohol Enhances Optical Brightener Agents in Board Coatings]

Paints

S-LEC B/K lends uniform pigment distribution and customizable viscosity control to paints. Its bonding strength leads to improved adhesion, enhancing bonds between paint and various substrates to prevent flaking and peeling.

Paint films with S-LEC B/K demonstrate greater flexibility and durability, making the end product resistant to cracking and weathering. Its durability and strength also increase water resistance, with the resin’s moisture barrier resulting in long-lasting product integrity. Ultimately, S-LEC B/K creates smooth, even paint and paint films with high gloss and excellent color retention.

S-LEC B/K polyvinyl acetal resin demonstrates excellent dispersion in inks and paints.

See S-LEC B/K grades and their specific applications.

Contact SEKISUI for S-LEC B/K Polyvinyl Acetal Resin

SEKISUI’s extensive experience in the high-performance plastics, environmental products and housing/urban infrastructure areas has earned it unparalleled specialty chemical knowledge. Environmentally friendly S-LEC B/K is a result of that sum of knowledge and expertise. The company continues to refine the product to meet the customer’s evolving requirements.

Contact SEKISUI for more information, or request samples of S-LEC B/K polyvinyl acetal resin. It is available as both an aqueous and a powder product.

Reach out to the SEKISUI tech services team for advice on the most suitable S-LEC B/K grade for an application.

Further Reading

- S-LEC B | SEKISUI SPECIALTY CHEMICALS

- S-LEC K(KW, KX) | SEKISUI SPECIALTY CHEMICALS

- S-LEC SV | SEKISUI SPECIALTY CHEMICALS

- S-LEC AS | SEKISUI SPECIALTY CHEMICALS

- S-LEC B/K Safety Data Sheet

- Polyvinyl Acetal Adhesives

- Characterization of Self-Adhesive Structural Tapes Modified With Polyvinyl Acetal Resins

- Influence of Polyvinyl Acetal Content on Overlap Shear Strength of Aluminum-SAT

- Role of Promoters in Improving Adhesions of Organic Coatings to a Substrate

- Epoxy Groups Conversion for SATs With Polyvinyl Acetals (After Thermal Curing)

Featured image via Pexels