Polyvinyl alcohol (PVOH) is beneficial as a creping adhesive component in paper tissue and towel manufacturing.

SEKISUI Specialty Chemicals offers Selvol PVOH, a versatile product that enhances the paper creping process. It lends key advantages to toilet tissue, paper towels, facial tissues, paper napkins, sanitary products and more.

What Is Paper Creping?

Paper creping is a process that creates a soft, textured paper product. It involves scraping a dried paper sheet off a Yankee dryer with a blade. The action causes paper fibers to break, creating creped paper structure. The result is tissue paper that can be soft, bulky and absorbent in varying degrees.

Manufacturers spray a coating, often containing adhesives like PVOH and polyamide epichlorohydrin (PAE), onto Yankee dryers for through-air drying (TAD). This forms a thin, continuous film. PVOH promotes and enhances crepes (microfolds) in paper web as it comes off the Yankee dryer.

Read more about PVOH in tissue and towel manufacturing.

This diagram shows the mechanism of a Yankee dryer with TAD for tissue creping.

Why Is PVOH Effective When Creping Paper?

PVOH is a multifunctional component in creping adhesive formulations for tissue and towel stock. As a specialty chemicals provider, SEKISUI tailors Selvol PVOH for critical characteristics:

- Rewettability. PVOH’s rewettability allows for controlled weakening of adhesive bonds by adding moisture. Controlled release is important for the creping blade to detach the paper from the Yankee dryer.

- Flexible film. Film-forming lets PVOH adhere paper to the Yankee dryer strongly while still releasing it properly. This ability contributes to efficient controlled adhesion and release.

- Good dry tack. This ensures a strong initial bond that’s necessary for creping. Without good dry tack, the paper web can slip or fail to adhere well, leading to poor creping.

- Eco-friendly. PVOH’s eco-friendliness aligns with the growing demand for sustainable paper products and produces greener manufacturing processes.

Manufacturers create high-quality, biodegradable tissue and towel paper more productively with Selvol PVOH.

See U.S. Patent 3,926,716 and U.S. Patent 4,440,898 for data on PVOH for improved tissue creping.

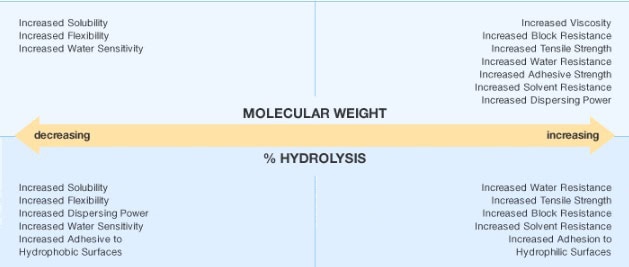

Selvol is highly customizable as its molecular weight and degree of hydrolysis change.

Why Choose PVOH as a Creping Adhesive Component?

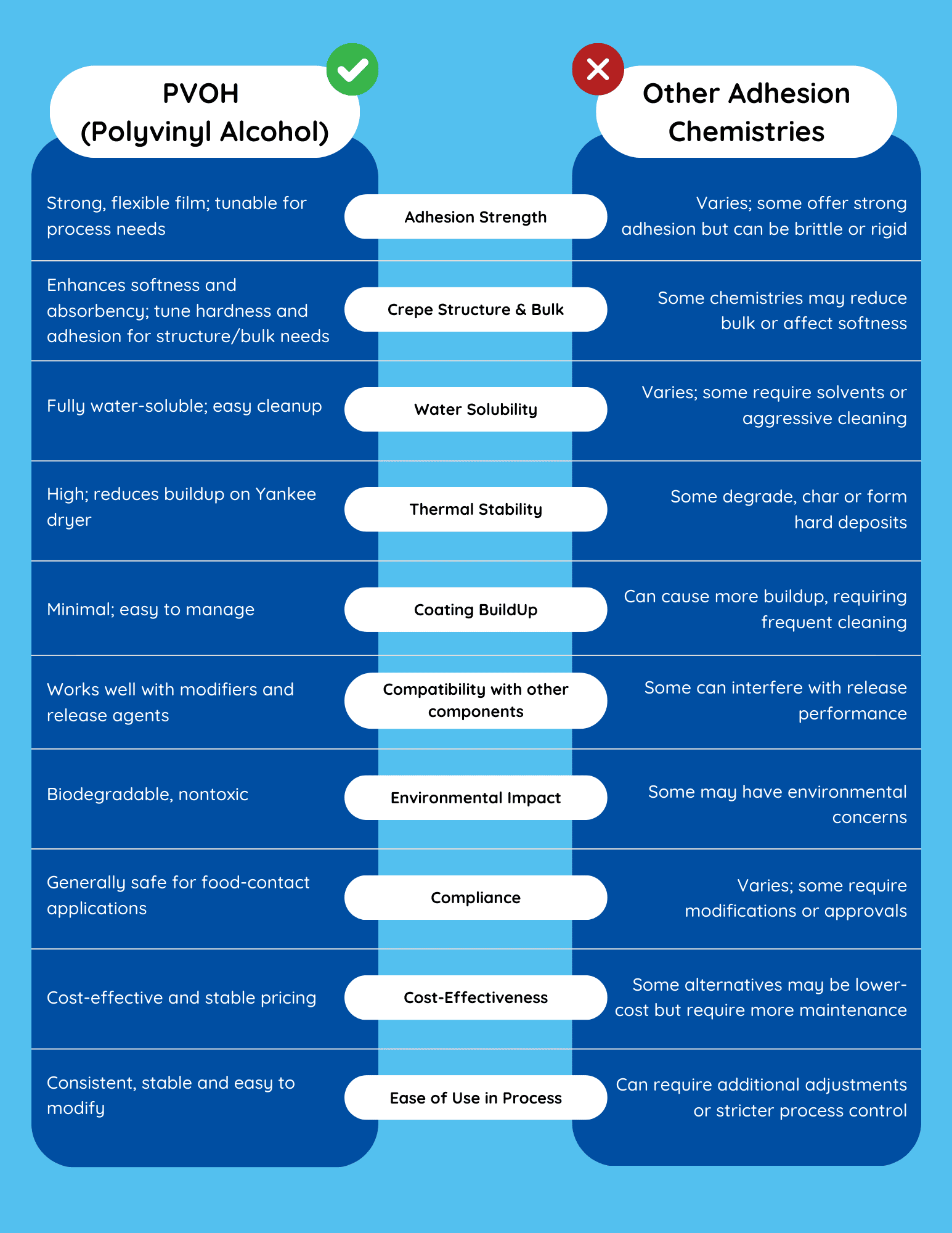

Manufacturers choose PVOH over other chemicals in creping formulations for many reasons, such as its versatility, adhesion and excellent quality. It blends and prepares easily, with a range of grades to meet customers’ needs for tissue paper products.

The infographic below compares Selvol PVOH to other common adhesion chemistries.

How Selvol PVOH Benefits Tissue and Towel Stock Creping

Selvol PVOH leads to superior creping in tissue and towel stock throughout manufacturing and in the end product.

More Efficient Processing

Selvol PVOH offers a more efficient run rate and less machine downtime during paper creping. The TAD process and Yankee dryer run better, with a longer creping blade life. Manufacturers save time and costs because they replace blades less frequently. They see fewer sheet breaks during the production process. Cleanup is also easy with water-soluble Selvol PVOH.

Tunable Adhesion

Selvol PVOH has tunable adhesion; manufacturers can control how strongly paper sticks to the Yankee dryer with precision. This allows the blade to crepe it correctly per the desired product. Manufacturers can adjust its adhesion to fine-tune their paper:

- Increase bulk

- Optimize absorbency

- Manufacture thin or thick papers

All the above exist on a sliding scale in relation to tunability. Manufacturers can increase or decrease bulk and optimize absorbency per specifications and grade requirements.

Tunable adhesion also allows the manufacturer to create softer and harder films. The coating’s hardness (its flexibility or rigidity) lets the blade penetrate the coating to crepe paper without damaging the blade or dryer, extending blade life.

Compatibility in Formulations

SEKISUI’s Selvol PVOH blends well with creping adhesive formulations, including those with softeners and release agents. It’s also compatible with and safe alongside Yankee dryer coating components. This saves manufacturers valuable time, costs and resources compared to other creping adhesive chemicals.

[Related: 9 Reasons To Use Selvol Polyvinyl Alcohol in Your Adhesive]

Versatility in Paper Products

Creped paper products improve with Selvol PVOH in adhesive formulations:

- Tissue paper

- Facial tissue

- Disposable hand towels

- Toilet paper

- Paper towels

- Disposable napkins

Coatings with Selvol PVOH can produce both thin and thick paper for lower-quality and higher-quality papers. For example, a cost-effective one-ply toilet paper is as achievable as an expensive, four-ply toilet paper.

Enhanced Softness

Selvol PVOH is a crucial tool for customizing a paper product’s tactile properties. Its rewettability and tunable adhesion create soft, thick and textured paper products. Greater adhesion leads to smoother, bulkier tissue, and lower adhesion creates less bulky, less smooth papers. Consistency in application is another advantage, ensuring the whole paper sheet has the same feel.

Biodegradability and Eco-Friendliness

Selvol PVOH lends a more eco-friendly approach than other products to tissue paper production. It helps achieve softness and strength through the creping process itself, reducing reliance on harsh bleaching agents like chlorine. Paper products’ biodegradability and lower environmental impact are clear advantages for manufacturers. PVOH is a generally recognized as safe (GRAS) chemical and meets regulatory requirements. It is non-DOT regulated for easy transportation and storage.

Read more about SEKISUI Specialty Chemicals’ commitment to sustainability.

Contact SEKISUI for Selvol PVOH

SEKISUI Specialty Chemicals is dedicated to formulating innovative, eco-friendly products that meet a wide range of applications.

Paper tissue manufacturers trust Selvol PVOH as a versatile creping adhesive component. They and their customers alike benefit from Selvol PVOH, with efficient processes and premium papers.

Contact SEKISUI for more information, or request samples of Selvol PVOH today. Reach out to the SEKISUI Technical Service team for expert advice, from support to troubleshooting to grade selection. Customer service is a top priority.

Read the Selvol PVOH product brochure.

Featured image via Pixabay