Packaging is essential in various industries such as pharmaceutical, food and electronics.

Food packaging and its technology are an essential part of the food industry as it is designed to protect and conserve the quality of foods without deteriorating their appearance, taste, smell, and provide the consumer information about the nutritional content.

Fifty years ago, most perishable items such as meat, cheese, or vegetables were packaged in glass or metal containers because they are durable and effective at extending the shelf lives of the food they contain. Even soda was packaged exclusively in glass containers. Diverse external factors, such as the expansion of global food markets, government regulations, the accessibility of raw materials, and consumer preferences, have caused the asx food packaging industry to be constantly in flux.

Plastic Food Containers Today

Today, petroleum plastics (synthetic polymers) are widely used for food packaging purposes. Such polymers include polyethylene tere- phthalate (PET), low and high density polyethylene (LDPE and HDPE respec- tively), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS).

Plastic containers don’t shatter or dent and are in many ways safer than glass or metal containers. Marketers also prefer plastic containers because they are amenable to printing and molding, making them aesthetically pleasing surfaces for promoting their contents.

Flexible packaging materials are not without drawbacks, however.

Evolution of Plastic Food Packaging

First generation plastic packaging for potato chips, for example, kept the chips fresh for only a few days, after which time they became stale and inedible. Even today, the shelf life of some products is longer in metal containers than in plastic containers and some products that require rigorous processing such as extreme heating during packaging are still packaged in metal containers.

However, flexible barrier packaging solutions continue to evolve and are widely used in stringent applications such as retort packaging and even for containing fish or other aromatic foods. Market needs in flexible barrier packaging include cost reduction, longer shelf life, lighter packaging, reduction in processing steps, improved consumer appeal and improved environmental footprint. In the past few years, sustainability has become a major issue and companies are trying to come up with new initiatives for the food packaging industry to maintain the quality and be environmentally responsible.

Below we discuss how Selvol Ultiloc polymers can help our customers meet these requirements.

Next-Generation Copolymers Used in Food Packaging

Selvol Ultiloc is a series of patented copolymers that expand the functionality of industry-trusted Selvol Polyvinyl Alcohol products. While Ultiloc retains some of the characteristics of conventional polyvinyl alcohols, Sekisui’s novel copolymer also exhibits certain enhanced, improved, or even new features for applications flexible packaging and extrusion. When compared to the polyvinyl alcohol polymer alone, Ultiloc copolymers offer a range of unique characteristics:

- Higher adhesion

- Improved crosslinking

- Faster dissolution

- Lower temperature solubility

These characteristics bring added efficiency and improved utility to many applications that already use polyvinyl alcohol and can be considered for new applications as well.

Current Food-Safe Packaging Requires Lots of Layers

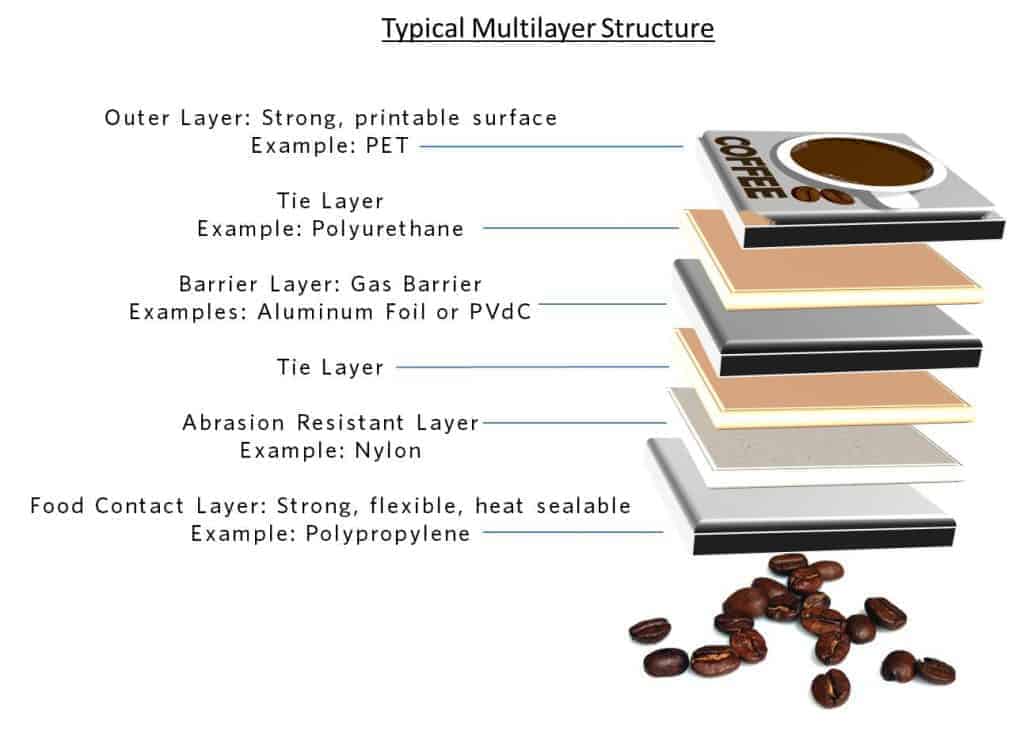

Compared to metal or glass, plastic materials are permeable to gases, such as oxygen, that can cause contents to decompose and become unusable. In order to overcome this, plastic barrier packaging generally consists of many layers, each layer imparting different attributes to the layered structure such as improved gas barrier properties, increased mechanical strength, puncture resistance, chemical resistance, good printability, and transparency.

Historically, a typical multilayer structure consists of:

- Outer layer

- Tie layer

- Barrier layer

- Abrasion-resistant layer

- Food-contact layer

An illustration of this typical multilayer structure is below.

By combining multiple materials in such a layered structure, it is possible to make a flexible barrier package that imparts shelf life stability similar to that of a metal or glass container, while achieving the other attributes mentioned above.

Metallic Food Packaging like Aluminum Has Its Disadvantages

Aluminum foil provides excellent gas barrier properties and has been used in flexible packaging for many years. Aluminum is impermeable to gases, but it must be applied in relatively thick layers (> 25 µm) to give excellent barrier properties, adding to product cost and weight. Furthermore, aluminum cannot be microwaved and is not recyclable. Polyvinylidene chloride (PVdC) is an excellent gas barrier polymer, but is being phased out of many packaging applications because of environmental concerns.

Flex Packaging’s Many Problems Solved by Utiloc Copolymer

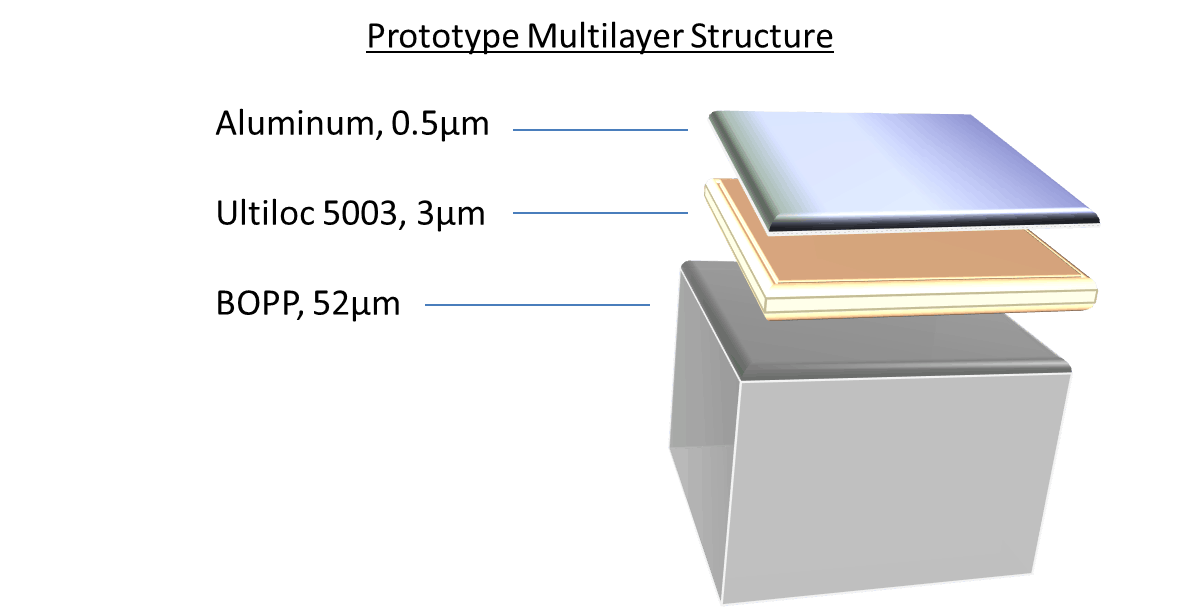

Selvol Ultiloc polymers are environmentally benign and offer an excellent alternative to PVdC and aluminum in many barrier packaging applications. Selvol Ultiloc copolymers have a surface energy greater than about 55 dynes/cm. This high surface energy allows the Selvol Ultiloc polymer to serve several functions in addition to having excellent gas barrier at low humidity. The high surface energy allows the Ultiloc film to function as a nucleation layer for efficient metal vapor deposition while also eliminating the need for tie layers in some multilayer structures. In order to demonstrate this, we recently produced a prototype multilayer film using Selvol Ultiloc 5003 as shown below.

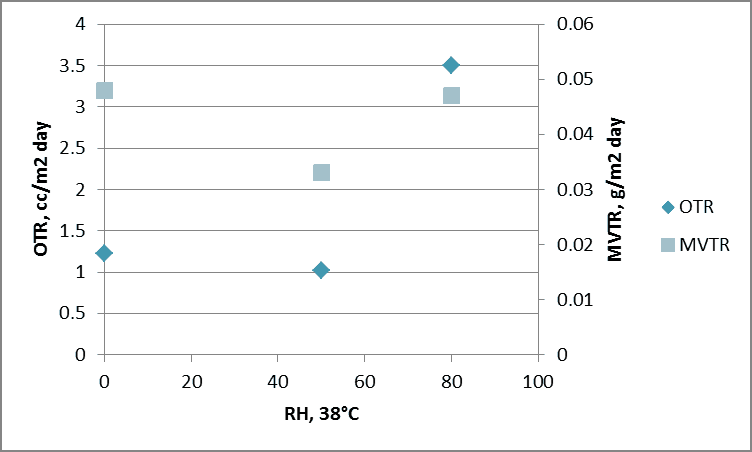

The prototype film was coated with a thin layer of aluminum. Even with such a thin metal layer, the barrier properties were good even at high humidity, as shown in the plot below.

This illustrates the possibility of using Selvol Ultiloc polymers in flexible barrier packaging systems as an environmentally acceptable replacement to aluminum foil and PVDC. With further optimization, we expect that lighter, essentially transparent barrier films can be produced with fewer converting steps and layers than existing multilayer barrier structures. This will reduce packaging and transportation costs and result in a more functional and sustainable product for the consumer.

To find out which grade will best enhance your products or processes, contact a Selvol polymers specialist at our Houston Technology Center.

Or request a sample today!